“Argon Influence in the PETEOS Silicon Oxide Deposition Process"

Carlos Eduardo Viana - ceviana@lsi.usp.br

The modern IC technologies are requiring more and more low temperature processes to minimize the thermal budget[1]. High quality silicon oxide thin films, deposited at low temperature have many applications in microelectronics such as: passivation coatings, interlevel dielectric, and gate dielectric in metal oxide semiconductor field effect transistors (MOSFET's) and thin films transistors (TFT's)(2)

.In this sense, Plasma Enhanced Chemical Vapor Deposition (PECVD) is one of the most important processes by its suitable characteristics such as good step coverage, low deposition temperature, high deposition rate, etc.[2].

The substrate, in single wafer PECVD reactors, is in direct contact with the plasma, thus the sample is in constant ions, electrons and photons bombardment. This operation mode is described as direct-plasma-enhanced CVD. Ion bombardment on silicon oxide films during the deposition process results in poor electronic properties[3]. However, the ions bombardment also activates the surface sites which promotes the film growth and densification [4]. In rf diode discharges, where the ion energy can exceed hundreds of eV, the substrate has higher probability to be damaged[5].

Another disadvantage of direct-plasma-enhanced CVD reactors is the difficulty to control the radicals and ions fluxes incident on the substrate. These fluxes are generated by the nonselective excitation and dissociation of the feedstock gases by electron impact. The fragmentation is not selective because the electron energy distribution, in a typical rf diode reactor, spans energies up to hundreds of eV[6].

We observed that adding argon to the gas mixture in the PETEOS silicon oxide deposition process, the quality of the film is drastically improved. In order to understand the physical and chemical mechanisms of the influence of the argon in the deposition process, we are developing this work and the first results are presentd below.

The silicon oxide deposition process was carried out in the following basic conditions: process pressure (P) of 1 Torr; temperature (T) of 375°C; TEOS flow (FTEOS) of 7.0 sccm oxygen flow (FO2) of 450 sccm, and RF power (Wrf) of 400 W.

|

|

We can observe in Figure 1 (film uniformity was considered proportional to the error bars) that the uniformity (measured in a Rudolph Research ellipsometer model Auto-El-NIR3 at the wavelength of 0.6328 mm) for deposited films is drastically improved adding the argon.

|

|

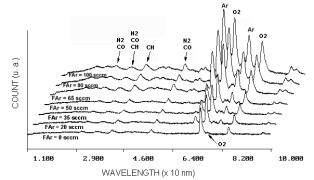

Figure 2 shows the deposition rate decreasing with the argon flow trending saturation and the best acquire uniformity is around 80 sccm of argon flow.Figure 3 shows the spectra obtained from the spectrophotometer analysis (Thermo Jarrell Ash Spectrophotometer, Princeton Instruments Inc. model: ST-120). the “CH” and “CO” bands increase as a function of argon flow. Probably, the argon ions increase the TEOS decomposition by physical collision, improving the uniformity of the deposited film.

|

|

Figure 3: Spectrophotometer analysis showing argon flow variation.

We can conclude that adding an argon flow to the gas mixture in the PECVD silicon oxide deposition process strongly influence the deposition rate and uniformity of the deposited layer. However, the physical and chemical mechanisms are not well understood yet.